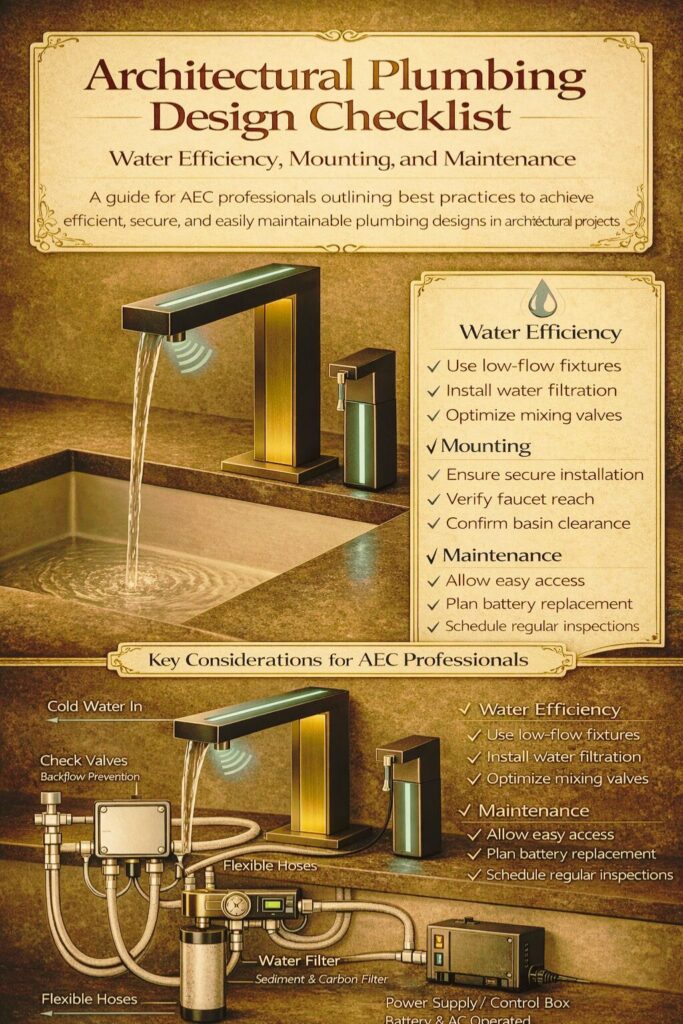

Architectural plumbing decisions show up where people touch the building. Restrooms, amenity wash areas, and public lavatories are high visibility spaces where water efficiency, mounting details, and maintenance access either work smoothly or become a long term problem.

This checklist is written for AEC teams coordinating commercial lavatory faucets and sink systems. It focuses on measurable outcomes: code compliance, sustainability documentation, usability, and maintainability over the lifecycle.

Water efficiency checklist

Confirm the use type before selecting flow rates

Public and private use lavatories are often treated differently in codes and standards. Start by classifying each restroom group in the project.

Public use lavatories typically include lobbies, shared restrooms, and common areas.

Private use lavatories typically include staff only areas, suites, and hotel guest rooms.

A practical baseline referenced in federal purchasing guidance is:

Public lavatory faucets: maximum 0.5 gpm

Metering faucets: maximum 0.25 gallons per cycle

Support document:

https://www.energy.gov/femp/purchasing-water-efficient-faucets-showerheads-toilets-urinals-irrigation-controllers-and

Use WaterSense when you need a clear efficiency benchmark

WaterSense is commonly used as a defensible baseline for bathroom sink faucets and accessories. It provides a maximum flow threshold and performance criteria that help teams write consistent schedules and submittal requirements.

Support page:

https://www.epa.gov/watersense/bathroom-faucets

Commercial focused support document PDF:

https://www.epa.gov/system/files/documents/2023-06/ws-commercial-watersense-at-work_Section_3.3_Faucets.pdf

Draft specification support document PDF for private lavatory faucets:

https://www.epa.gov/system/files/documents/2024-12/watersense-draft-v2-lavatory-faucets-specification_12-2024.pdf

Align with LEED indoor water expectations early

If the project is pursuing LEED, confirm the rating system and version in use, then confirm the fixture documentation requirements early. This reduces late changes and makes indoor water modeling more consistent.

USGBC indoor water use reduction references:

https://www.usgbc.org/node/2751480

https://www.usgbc.org/node/2751242

Do not treat low flow as the only goal

Water savings on paper can disappear if the faucet causes splash, long activation time, or user frustration that leads to repeated triggers or aerator removal. Include performance and commissioning in the plan.

Water efficiency coordination items to confirm on drawings and submittals:

- Maximum gpm stated at a defined pressure, commonly 60 psi

- Metering discharge stated in gallons per cycle when applicable

- Flow control device and part number matches the scheduled gpm

- Outlet type supports splash control and comfortable handwashing

- Commissioning plan includes sensor run time tuning if touchless

Mounting and geometry checklist

Choose the mounting type that fits the wall, counter, and maintenance plan

Common mounting approaches include deck mount single hole, deck mount widespread, and wall mount.

Early coordination details that prevent rework:

- Countertop thickness and hole pattern

- Spout reach and spout height relative to basin depth

- Drain location relative to spout outlet

- Clearances for handles or sensor windows

- Location of mixing valves and stops for service access

Confirm ADA clearances and operable parts

For accessible lavatories, the approach, knee and toe clearance, and the location of controls matter. Use the Access Board guide during layout, not after the casework is finalized.

Guide page:

https://www.access-board.gov/ada/guides/chapter-6-lavs-sinks/

Guide PDF:

https://www.access-board.gov/files/ada/guides/lavs-sinks.pdf

Accessibility coordination items that often get missed:

- Deep counters can push faucets out of reach

- Soap and towel dispensers need to be placed within the usable reach zone

- Faucet controls must be operable without tight grasping, pinching, or twisting

- Drain and hot water components should be addressed so they do not create contact hazards where applicable

Sensor systems checklist

Touchless faucets should be coordinated like a small MEP system. The sensor package affects power, access, commissioning, and long term reliability.

Sensor performance depends on layout

Common causes of callbacks:

- Activation zone is not where users naturally place hands

- False triggers from reflections, mirror placement, or lighting

- Run on time is too long

- Flow is too low for comfortable rinse, causing repeat activations

Commercial operational support document PDF:

https://www.epa.gov/system/files/documents/2023-06/ws-commercial-watersense-at-work_Section_3.3_Faucets.pdf

Power and controls coordination

Confirm early:

- Battery versus hardwired power strategy

- Control box size and mounting space under the counter

- Service clearance for battery replacement and sensor adjustment

- Cable routing and protection from cleaning activities

- Access to shutoff valves without removing casework

Healthcare and low use spaces

If the building includes healthcare zones or low use restrooms, coordinate flushing and operations planning to reduce stagnation risk. Consider how the owner will maintain the system after occupancy.

Industry guidance PDF:

https://apic.org/Resource_/TinyMceFileManager/Practice_Guidance/APIC-ASHE-Statement-electronic-faucets.pdf

Maintenance checklist

Maintenance is where good specifications prove themselves. A faucet system should be serviceable without dismantling the vanity or damaging finishes.

Service access

Confirm that the following can be reached and replaced:

- Cartridges and seals

- Flow control devices and aerators

- Solenoids and filters if present

- Batteries and control modules

- Mixing valves and check valves where used

- Isolation valves and stops

Standardize parts where possible

In multi restroom projects, standardization reduces lifecycle cost and downtime:

- Use consistent cartridge platforms

- Use consistent aerator and flow control families

- Use consistent battery types and replacement procedure

- Require a spare parts package aligned with operations expectations

Cleaning compatibility

Finish failure is often a maintenance problem, not a product problem. Ensure the O and M package includes:

- Approved cleaners for the finish

- Prohibited abrasives

- Instructions for sensor window cleaning

- Guidance on mineral buildup removal without damaging coatings

Submittals, documentation, and closeout checklist

Submittals that reduce RFIs

Require the submittal to include:

- Flow rate and test condition

- Installed flow control part number

- Compliance claims and certifications requested by the owner

- Rough in requirements and mounting template

- Sensor settings range and run time adjustment method

- Power details and expected battery life assumptions

- Maintenance instructions and replacement parts list

Closeout and commissioning

Commissioning tasks that prevent early complaints:

- Verify the stream lands in the basin working zone

- Adjust sensor range and run time for real users and basin geometry

- Verify mixing delivers stable temperature and does not create scald risk

- Verify under counter controls are accessible for service

- Confirm as built documentation includes the installed flow control device

Printable checklist summary

Water efficiency

- Classify public vs private lavatories

- Confirm baseline limits for public and metering where applicable

- Use WaterSense benchmarks where appropriate

- Align fixture selections with LEED indoor water approach if applicable

- Require flow control part numbers and defined test pressure

Mounting

- Confirm hole pattern, counter thickness, and basin geometry

- Verify spout reach and height reduce splash

- Confirm ADA approach and clearances

Sensor systems

- Plan power, control box space, and service access

- Commission sensor range and run time

- For healthcare and low use areas, coordinate stagnation risk response

Maintenance

- Confirm access to cartridges, batteries, solenoids, filters, and valves

- Standardize parts across restroom groups where possible

- Include cleaning and finish care in O and M

Documentation

- Require flow control part numbers and performance data in submittals

- Include templates, rough in, and sensor setting ranges

- Deliver as built schedules and spare parts lists

Conclusion

Architectural plumbing design works best when water efficiency, mounting details, and maintenance access are treated as one coordinated scope. When the faucet, basin, countertop, and control package are aligned early, teams reduce late stage RFIs, improve user experience, and make long term operations predictable. The strongest commercial restroom specifications support both sustainability targets and real world serviceability after occupancy.

- DOE FEMP purchasing guidance for water efficient faucets and code limit summary energy.gov

- EPA WaterSense bathroom faucet baseline epa.gov

- EPA WaterSense at Work commercial faucets support document (PDF) epa.gov (PDF)

- EPA WaterSense draft specification for Private Lavatory Faucets Version 2.0 (PDF) epa.gov (PDF)

- USGBC indoor water use reduction references usgbc.org

- USGBC indoor water use reduction references (additional) usgbc.org

- U.S. Access Board ADA guide Chapter 6 Lavatories and Sinks access-board.gov

- U.S. Access Board ADA guide Chapter 6 Lavatories and Sinks (PDF) access-board.gov (PDF)

- Healthcare evidence: bacterial contamination associated with electronic faucets (journal article) cambridge.org

- Healthcare guidance: APIC–ASHE statement on electronic faucets (PDF) apic.org (PDF)

Location: Austin, TX

Profile: Sustainable design consultant specializing in low-flow, touchless water delivery systems. Focused on water conservation strategies and system integration for LEED and Green Globes projects.

No responses yet