Commercial restroom faucets are often specified for performance first, but finishes and base materials have a direct impact on how those fixtures look and perform after years of use. In high traffic interiors, a finish that fails early creates a visible quality issue and a maintenance problem. It can also trigger premature replacement, which undermines sustainability goals.

For architects, interior designers, and specifiers, the best approach is to treat faucet finishes as part of the building envelope at a micro scale. You are selecting a surface that must resist abrasion, chemical cleaning, hard water spotting, and sometimes vandalism. This guide explains the most common commercial faucet materials and finishes, how they behave in real installations, and how to write finish requirements that hold up in demanding projects.

Why finishes and materials matter in commercial bathrooms

Finish selection is not only an aesthetic decision. In commercial interiors, finish and material choices affect:

- Long term appearance under frequent cleaning

- Corrosion resistance in humid environments

- Resistance to fingerprints and water spotting

- Compatibility with disinfectants and harsh chemicals

- Repairability and availability of replacement parts

- Compliance requirements for drinking water contact components

A good looking faucet on day one is easy. A faucet that still looks intentional after five years of heavy use is a specification decision.

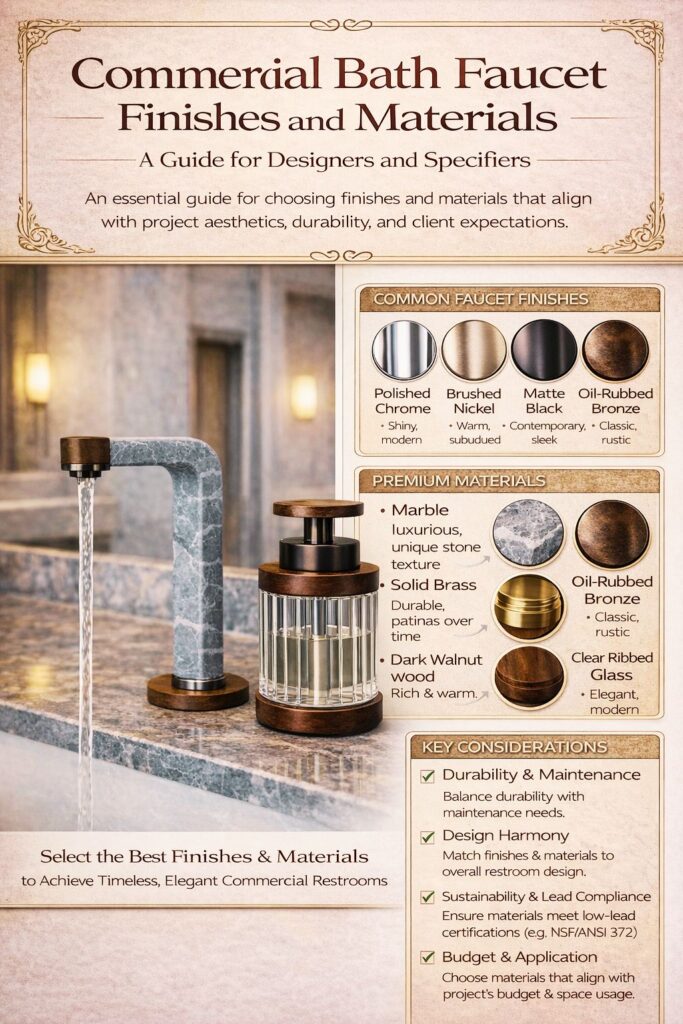

1) The base materials designers and specifiers see most often

Brass

Brass remains widely used because it machines well, resists corrosion, and supports stable threaded connections. In commercial faucet bodies, brass is frequently paired with chrome, PVD finishes, or specialty coatings.

From a compliance standpoint, many drinking water contact products are expected to meet standards related to lead content and leaching. The U.S. Consumer Product Safety Commission recommends checking for NSF/ANSI 61 certification and lead free fixtures labeled NSF/ANSI 372.

https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Lead-in-Water-Faucets

NSF also states that faucets and plumbing products intended for contact with drinking water should be tested and certified to NSF/ANSI Standard 61.

https://www.nsf.org/consumer-resources/articles/faucets-plumbing-products

Stainless steel

Stainless steel is commonly specified in environments where durability, cleaning, and corrosion resistance are priorities. It is often used in healthcare, education, and public facilities where finish damage or corrosion is unacceptable. Stainless can also support modern design language because it reads as honest and technical.

Zinc alloy and mixed castings

Some products use zinc alloy or mixed cast components. These can be cost effective, but long term durability depends heavily on plating quality, coating thickness, and the environment. For high traffic commercial use, it is safer to demand robust coating performance requirements and validation testing.

2) The most common commercial faucet finishes and where they work best

Polished chrome

Polished chrome remains the default commercial finish because it is widely available, easy to match, and generally durable when properly plated. It also fits most interior palettes.

What to know:

- High reflectivity shows fingerprints and water spots

- Works well for public restrooms because it is familiar and easy to maintain

- Durability depends on plating quality and thickness

Brushed nickel and satin nickel

Brushed and satin finishes reduce visible fingerprints and can complement warm or neutral interior palettes. They are common in hospitality and high end workplace interiors.

What to know:

- Better at hiding fingerprints than polished chrome

- May vary between manufacturers, so matching across accessories requires coordination

- Some satin finishes require careful cleaning to avoid uneven sheen

Matte black

Matte black continues to be popular in modern interiors. In commercial settings, the challenge is long term appearance because black finishes can show mineral deposits, soap residue, and abrasion more clearly than mid tone metals.

What to know:

- Works best where cleaning protocols are consistent and approved for the coating

- Requires higher finish performance to resist abrasion

- Often looks best when coordinated with dispensers and other hardware

Brushed stainless and satin stainless

These finishes support clean modern interiors and work well where durability and low visual noise are priorities.

What to know:

- Consistent look with stainless accessories and partitions

- Good choice for environments that emphasize maintenance and longevity

- Can still show water spotting, but typically less than polished chrome

3) Finish technologies you should understand before specifying

Designers often specify a color, but specifiers need to understand the technology behind it. Two faucets with the same visual finish can behave very differently depending on how that surface was created.

Electroplating and chrome plating

Traditional plating builds a metallic finish layer over the base material. Quality depends on process control and thickness.

Powder coating

Powder coating can create durable color finishes, including matte black. Performance depends on adhesion, film thickness, and resistance to cleaning chemicals.

PVD finishes

Physical vapor deposition finishes are often used for higher durability metallic tones. Many commercial specifiers use PVD to achieve better scratch resistance compared to some painted finishes.

Why testing matters

Because finish technology varies, performance should be verified through standardized testing methods rather than assumed.

Salt spray testing is commonly used to evaluate corrosion resistance of coatings. ASTM B117 is a widely referenced test method for salt fog exposure.

https://coteclabs.com/method/astm-b-117/

https://en.wikipedia.org/wiki/Salt_spray_test

A specifier does not need to be a materials scientist, but it is reasonable to request documented corrosion resistance test results for high exposure environments such as coastal regions, natatorium adjacent spaces, and locker rooms.

4) Cleaning, chemistry, and why finishes fail in real life

Commercial restrooms are cleaned frequently, often with disinfectants that are harsh on coatings. Finish failure is commonly caused by:

- Abrasive pads and scrubbers that scratch protective layers

- Incorrect chemical cleaners that strip coatings

- Leaving chemical residue on surfaces

- High mineral content water that leaves deposits

- Neglecting manufacturer recommended cleaning protocols

When a finish fails, the fixture can become visually inconsistent with the interior design language. It can also create a perceived cleanliness issue even when the restroom is clean.

A practical approach for AEC teams is to specify finishes that tolerate standard commercial cleaning routines and to coordinate with facilities teams so cleaning protocols match the finish requirements.

5) How finishes connect to accessibility and usability

Finish and material selection also intersects with accessibility. If a finish choice drives a move toward certain control types, it can impact compliance and usability.

The U.S. Access Board ADA guidance for lavatories notes that faucets must comply as operable parts. Controls should be usable without tight grasping, pinching, or twisting of the wrist.

https://www.access-board.gov/ada/guides/chapter-6-lavs-sinks/

This often encourages:

- Lever handles

- Touchless controls

- Push type controls

For specifiers, this means finish selection should remain consistent across the chosen control strategy and the broader restroom accessory set.

6) Sustainability and health considerations beyond appearance

Finish selection has lifecycle implications. If a finish cannot withstand real use, replacement becomes more frequent, which increases material waste and embodied impacts. Sustainability also intersects with drinking water contact safety.

The Consumer Product Safety Commission advises choosing faucets that comply with NSF/ANSI 61 and choosing lead free fixtures labeled NSF/ANSI 372.

https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Lead-in-Water-Faucets

NSF explains NSF/ANSI 372 as a standard methodology for determining and verifying product compliance to minimize lead contamination.

https://www.nsf.org/knowledge-library/nsf-ansi-can-372-technical-requirements

For projects with strict owner standards, adding NSF/ANSI 61 and NSF/ANSI 372 requirements in Division 22 can simplify approvals and reduce late stage submittal issues.

7) Specification language designers and architects can use

Below are practical spec ideas that help finishes hold up in commercial projects.

A) Require clear finish definition and consistency

- Specify finish name and technology where possible, such as polished chrome plating or PVD brushed stainless

- Require matching finish across faucet, trim, soap dispensers, and other visible hardware

B) Require corrosion and durability documentation for high risk environments

- Coastal locations

- Natatorium adjacent areas

- Locker rooms with high humidity

Reference salt spray test method as a performance approach when needed:

https://coteclabs.com/method/astm-b-117/

C) Include cleaning compatibility requirements

- Require manufacturer recommended cleaning methods

- Prohibit abrasive pads and harsh chemicals if the finish is sensitive

- Provide closeout documentation for facilities teams

D) Include drinking water contact compliance when applicable

- NSF/ANSI 61 for safety of drinking water components

https://www.nsf.org/consumer-resources/articles/faucets-plumbing-products - NSF/ANSI 372 for lead content methodology and compliance

https://www.nsf.org/knowledge-library/nsf-ansi-can-372-technical-requirements

8) Selecting finishes by building type

Office and workplace interiors

- Often benefit from satin or brushed finishes that reduce fingerprints

- Touchless controls are common in shared restrooms

- Matte black can work in premium projects if cleaning practices align

Hospitality

- Finish selection is often part of the brand experience

- Warm metals, brushed finishes, and coordinated accessories are common

- Durability is critical because guests notice wear quickly

Healthcare and education

- Focus is on cleanability, durability, and consistent operation

- Stainless and durable plated finishes are common

- Avoid finishes that require gentle cleaning only

Transit, stadiums, public facilities

- Vandal resistance and maintenance access matter

- Polished chrome remains popular for resilience and familiarity

- Specify robust finish performance and replacement parts availability

9) Common finish mistakes in commercial faucet specifications

Finish failures in commercial restrooms rarely happen because a finish was “bad.” They happen because the finish was specified without matching the real conditions of the space, including cleaning habits, water quality, traffic level, and how the fixture is touched every day. Below are the most common mistakes, why they occur, and what designers and specifiers can do to avoid them.

Mistake 1: Selecting a finish without confirming cleaning protocols

This is the number one reason commercial faucet finishes fail early.

What happens in real buildings

Most commercial restrooms are cleaned fast, on a schedule, and often by rotating staff. That means cleaners may use:

- Strong disinfectants

- Bleach based products

- Acidic cleaners for mineral scale

- Abrasive pads or scrubbers

- Spray and leave methods without rinsing

Even a high quality coating can degrade if harsh chemicals are left on the surface. Many matte and specialty finishes are more sensitive to this than polished chrome.

Mistake 2: Not coordinating finish across the restroom system

A faucet is not isolated. It sits next to dispensers, grab bars, flush valves, and door hardware. In modern commercial interiors, this “system look” matters, especially in premium workplaces and hospitality.

What happens in real projects

Design intent may specify “brushed nickel” or “matte black,” but:

- Different manufacturers interpret the same finish name differently

- Two satin finishes can have different gloss levels

- Color tone can lean warm, neutral, or cool

- Textures can be fine brushed or aggressive brushed

If the faucet does not match accessories, the restroom looks disjointed even if every item is individually high quality.

Mistake 3: Overusing very dark finishes in high mineral water areas

Dark finishes often look clean and modern in renderings, but they behave differently in real buildings.

What happens in real buildings

In areas with hard water, faucets develop:

- Mineral deposits

- Chalky rings around aerators

- Soap residue that dries white

- Water spots that show more strongly on dark surfaces

Matte black can still work in commercial interiors, but it requires maintenance planning. Without consistent cleaning, a dark finish can look “dirty” even when the restroom is cleaned daily.

Mistake 4: Assuming all brushed finishes match

Brushed nickel, satin nickel, brushed stainless, and similar names vary widely between manufacturers. Specify coordination requirements for accessories.

What happens in procurement

Finish labels like “brushed nickel,” “satin nickel,” “brushed stainless,” and “satin stainless” are not standardized. A brushed nickel from one manufacturer may look like satin stainless from another. The angle of the brushing, reflectivity, and even base metal tone can shift the look.

Conclusion

Commercial bath faucet finishes and materials should be specified like any other high touch building component. The best finish choice supports the interior design concept, performs under harsh cleaning and high traffic use, and stays visually consistent over time. When specifiers pair finish selection with durability documentation, accessibility requirements, and drinking water contact compliance, the fixture package becomes more predictable and easier to maintain.

- NSF guidance on faucets and plumbing products and NSF/ANSI 61 nsf.org

- NSF faucets and plumbing resources (consumer guidance hub) nsf.org

- CPSC guidance on lead in water faucets and NSF/ANSI 61 and 372 references cpsc.gov

- NSF/ANSI/CAN 372 technical requirements overview nsf.org

- Salt spray corrosion testing reference (ASTM B117 method) coteclabs.com

- Salt spray test overview (general reference) wikipedia.org

- ADA guidance for lavatories and faucets as operable parts access-board.gov

Location: Austin, TX

Profile: Sustainable design consultant specializing in low-flow, touchless water delivery systems. Focused on water conservation strategies and system integration for LEED and Green Globes projects.

No responses yet